Products Series

The main products include various CNC machining centers, CNC milling machines, CNC lathes, milling and drilling machines, multi-functional machine tools and conventional lathes.

-

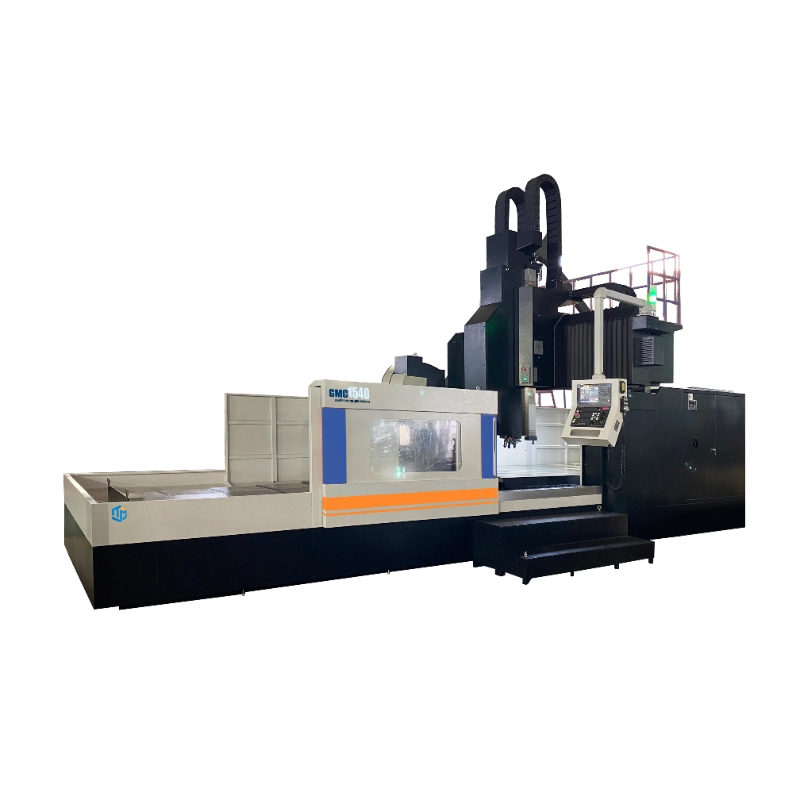

CNC Gantry-Type Machining Center

A Gantry Machining Center is a heavy-duty CNC machine tool designed for large-scale and high-precision machining. It features a gantry-structured frame for strong rigidity, enabling stable processing of large workpieces like molds, machine beds, and aerospace components.

Why Gantry-Type Machining Centers Are the Ideal Choice for Large and Heavy Workpieces

It's common knowledge that small workpieces are machined with small machines, and large workpieces with large machines. However, the reasons behind this are often unclear. Large workpieces also present their own production and processing challenges. These challenges typically include: achieving the required machining accuracy, ensuring stability during machining, maintaining precise positioning during multiple movements, overcoming surface roughness caused by vibration, and mitigating the cumulative errors resulting from repeated clamping.

Therefore, to avoid wasting time and labor costs due to using unsuitable machines, gantry-type machining centers are the appropriate choice for machining large workpieces. Why are gantry-type machining centers more suitable? Our engineers will explain from the following aspects:

What makes gantry machines so stable under heavy cutting?

Gantry-type machining centers primarily employ a symmetrical structure with double columns and a crossbeam. The advantage of this structure is that the cutting force travels through the spindle → crossbeam → column → bed, forming a complete and symmetrical force path. This results in less structural deformation and higher stability under heavy cutting conditions. The bed, column, and crossbeam of a gantry-type machining center are typically larger and thicker in cross-section, using high-strength cast iron or welded structures. If you’ve worked with heavy machinery, you know this kind of structure is stiffer and absorbs vibration better. This is why structural stability is one of the biggest advantages of gantry-type machining centers.

Fewer errors from a single clamping:

When machining complex workpieces, we may need to clamp multiple times to meet basic machining requirements. However, multiple clampings can lead to problems, as accumulated errors during machining ultimately result in wasted effort. With a gantry-type machining center, most machining operations can be completed in a single clamping. This results in better positional consistency, shorter clamping and alignment times, and higher overall machining efficiency. For workshops handling medium to large-scale batch production, this directly impacts production efficiency and cost control.

How to Choose the Right Gantry?

While many factories know they need a gantry-type machining center to assist with machining, which model best suits their needs? TopMade will use our GMC1016 and GMC2540 as examples:

For workshops machining medium-sized but heavy workpieces (such as small mold frames, mechanical parts, or thick steel plates), our GMC1016 is ideal. It is compact enough to save space, yet robust enough to handle heavy-duty cutting. Here are its key features:

- Table size: 1600 × 1000 mm (provides ample space for medium-sized parts, avoiding overcrowding)

- Spindle taper: BT50 (ideal for heavy-duty cutting, ensuring secure and stable tool clamping)

- Maximum spindle speed: 7000 rpm (balances the high torque required for roughing with the fine surface finish needed for finishing)

- Maximum table load: 3.5 tons (easily handles heavy parts that smaller machine tools struggle to handle)

If you are machining truly oversized, heavy-duty parts—such as large structural components, full-size machine tool frames, or large industrial steel plates—our GMC2540 is designed to meet the challenge. This machine tool is designed for industrial-grade machining, with extremely high requirements for size and load capacity. Its specifications fully meet these needs:

- Table size: 4000 × 2500 mm (easily accommodates even the largest workpieces, eliminating the need to spread them across multiple machine tools)

- Spindle taper: BT50 (consistent with the GMC1016, ensuring reliable heavy-duty cutting performance)

- Maximum spindle speed: 6000 rpm (optimized for high torque, enabling efficient machining of heavy, high-toughness materials)

- Maximum table load: 24 tons (capable of machining large castings and structural components without bending or deformation)

If you are evaluating whether a gantry-type machining center is suitable for your production needs, please feel free to share information about typical workpieces and machining requirements. TopMade's professional engineering team can help you assess whether models such as the GMC1016 or GMC2540 meet your application requirements, or whether there are other more suitable configurations.

-

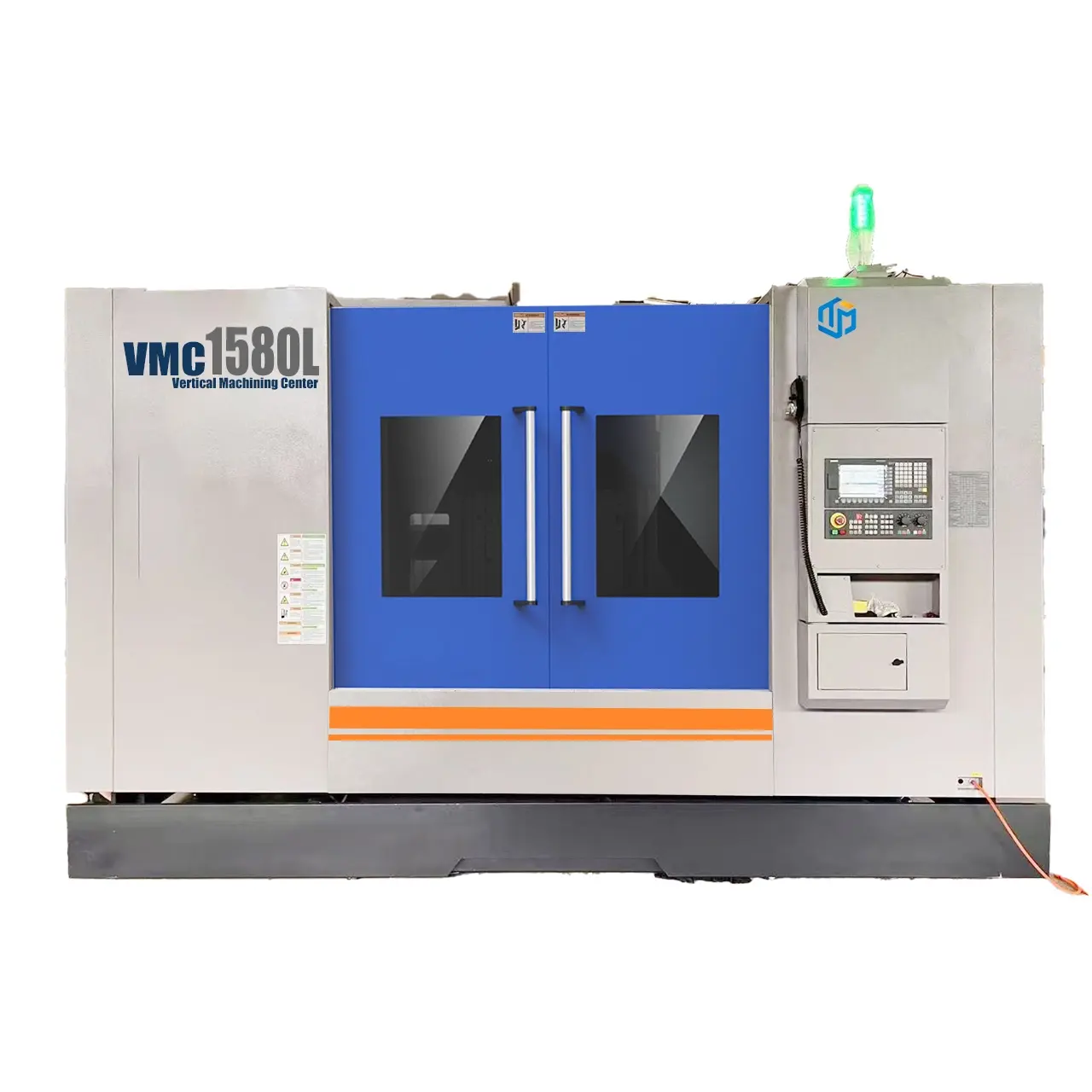

Vertical Machining Center

Vertical machining center (VMC) is a high accuracy CNC machine which the spindle axis is perpendicular to the worktable.

What is vertical maching center?

VMC is widely used in metal machining(milling,drilling,boring ,tapping and so on),the macine always with the tool magazine and automatic tool change system.

- Umbrella type tool magazine:12pcs or 16pcs,sutiable for small size VMC

- Disk type tool magazine:24pcs or 30pcs,suitable for medium size VMC

- Chain type tool magazine:40pcs or 60pcs for large size VMC

VMC can continuous finsihed different steps machining,widly used for mechanical manufacturing (eg:parts machining,mold production),with the advantages of efficiency and percision.It is the core equipment in the metal processing industry.

Why choose top made?

Top made is a professional manufacturer of CNC

machinery,more 10 years production experience,two production lines for vertcial machining center and CNC lathe.One sale team with 10 sales and half of the team are have more than 15 years machinery sales experience.We can supply you correctly plan according to your requirements.

Machine parts from well-known brands:

- Spindle:Volis,Royal,KENTURN

- Ball screw and linear guide:PMI,THK,HIWIN

- Tool magazine:KENTURN,OKADA,ASIMACH

Professional technical team:

- 5 persons professional engineer team

- 24 hours online service

- Support Overseas installation and commissioning

Each bussiness start from the customer recevie the machine,support the best after service is one of the important business philosophy for Top machine.

Choosing Topmade means choosing a stable and reliable machining solution. We focus on developing high-rigidity structural designs to ensure our equipment maintains superior precision during continuous heavy cutting. Combined with high-performance CNC systems and intelligent programming software, we achieve efficient automated production. Our entire product line undergoes rigorous testing and is suitable for machining complex parts and precision molds, helping companies improve productivity and product consistency.

-

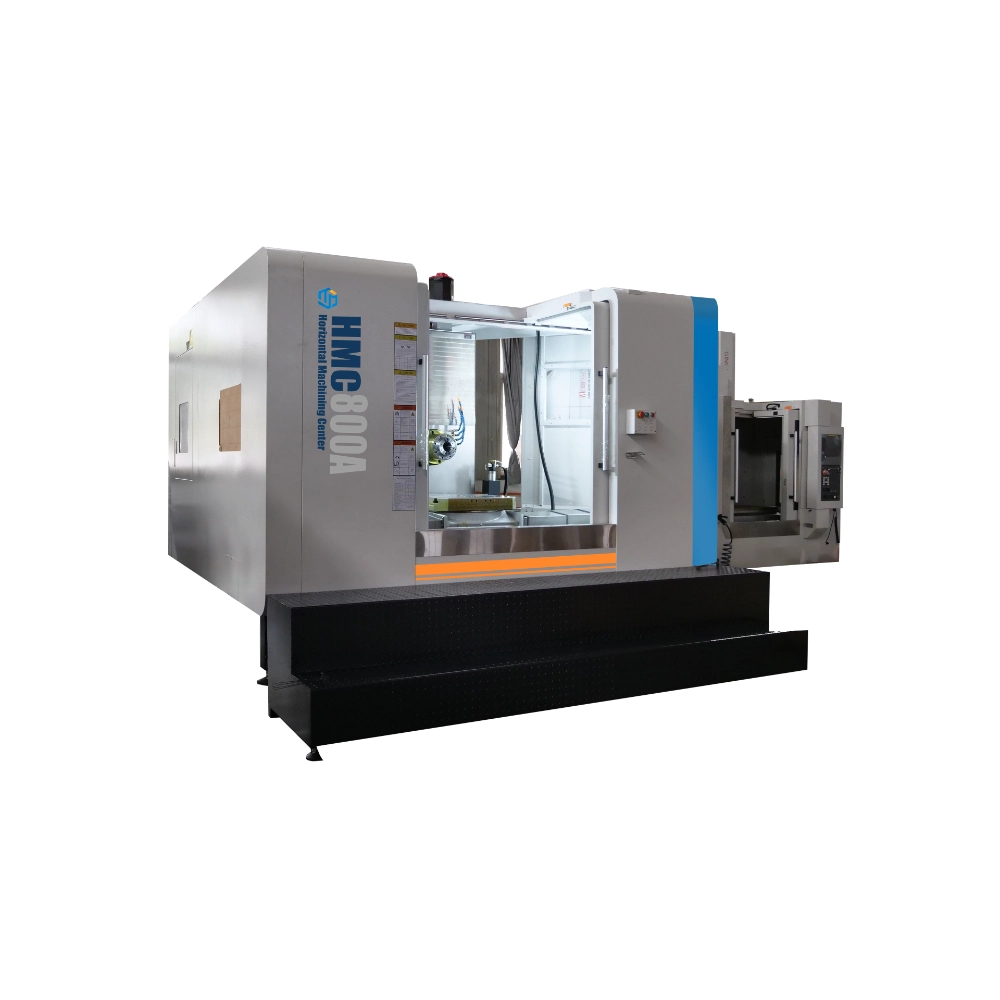

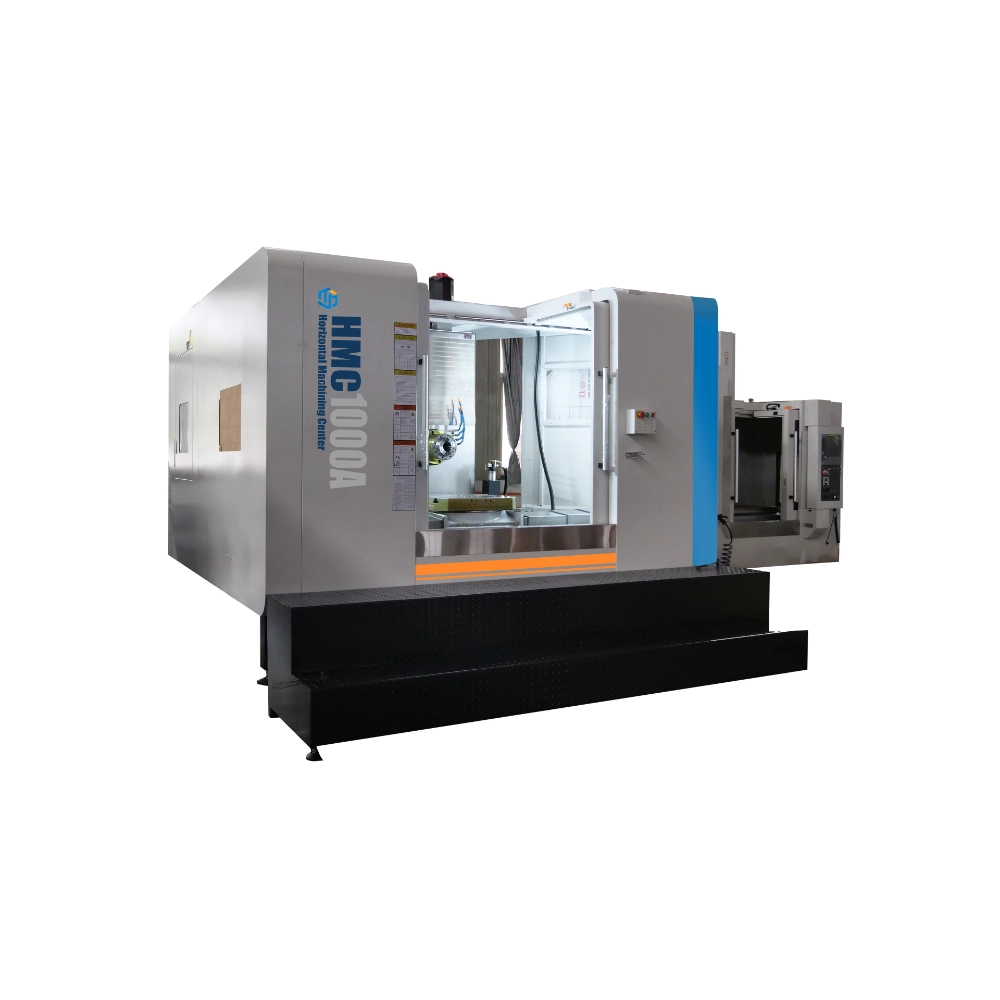

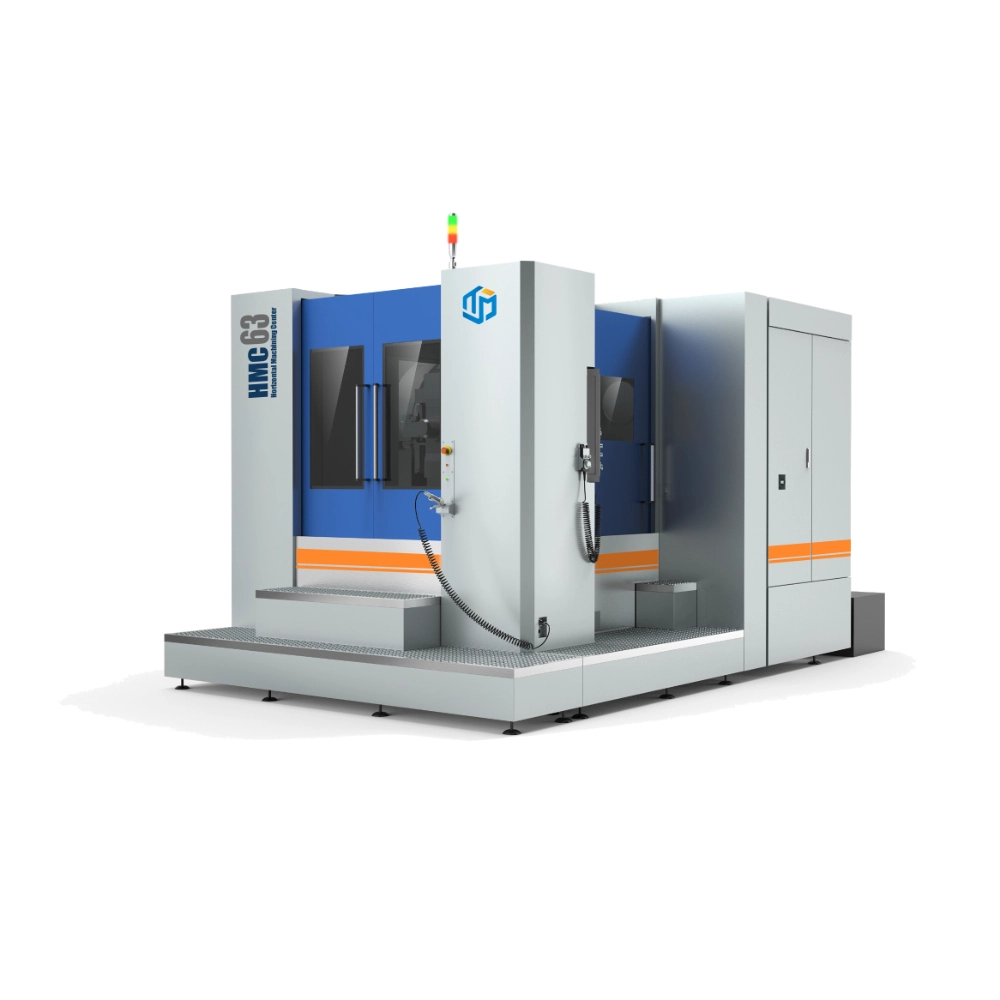

Horizontal Machining Center

A Horizontal Machining Center is a CNC machine tool where the spindle is oriented horizontally, and it uses automatic tool changers and pallet systems to machine multiple sides of a part with very little human intervention.

-

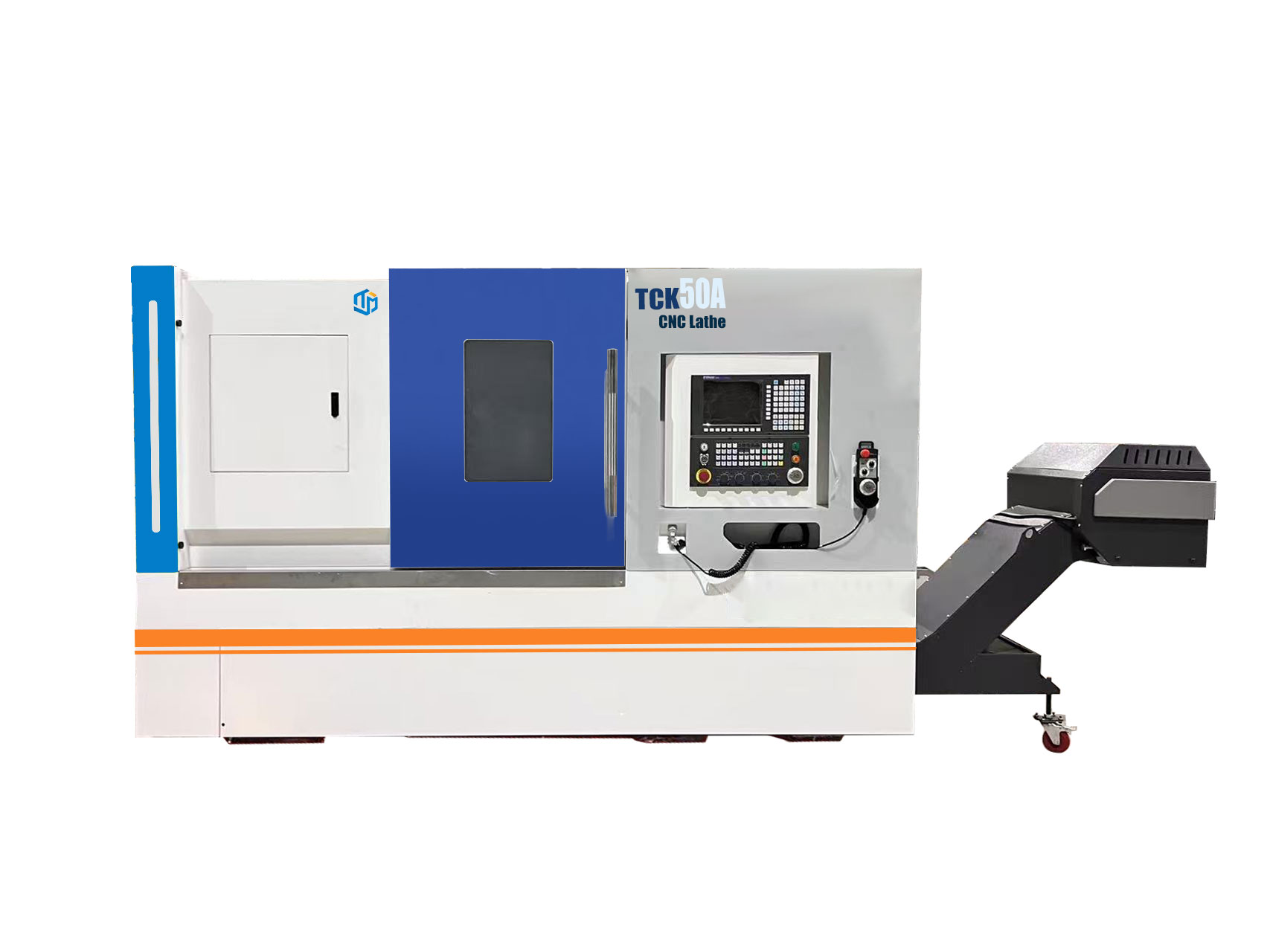

CNC Lathe

A CNC Lathe is a computer-controlled machine that spins a block of material (like metal or plastic) and uses stationary cutting tools to precisely shape it into a round, symmetrical part.

-

Vertical Lathe

A machine tool designed for machining large, heavy workpieces with a large diameter and short length. The workpiece is clamped on a horizontal rotating table, and the cutting tools are mounted on vertical and cross rails, allowing for turning, facing, boring, and grooving operations.

-

Conventional Machine Tools

The XL6436CL universal milling machine is engineered to redefine flexibility and reliability in precision machining, making it a standout choice for small-to-medium enterprises, workshops, and industrial production lines. Its core strengths address diverse machining needs while ensuring consistent performance.

-

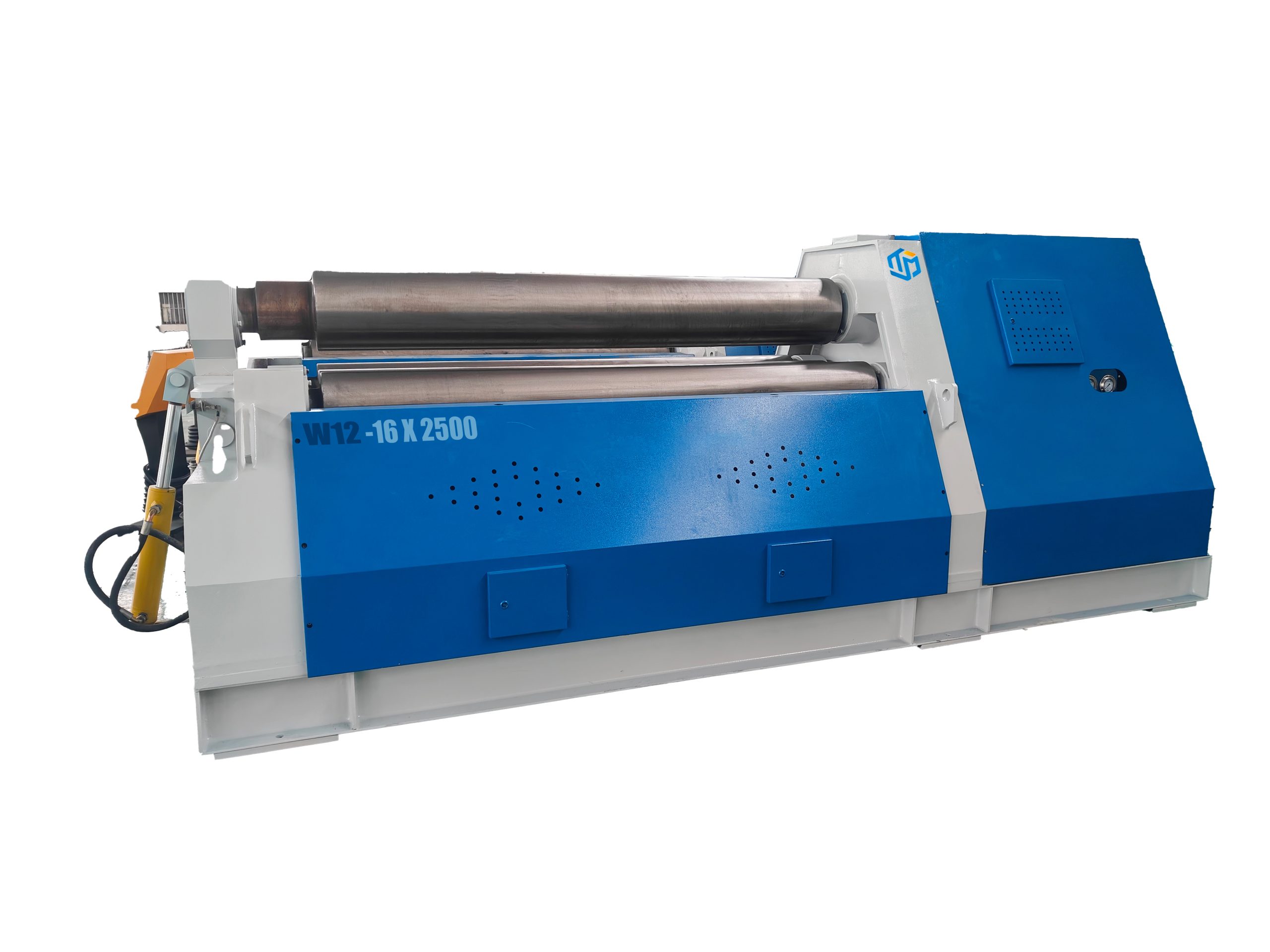

Sheet Metal Machine Tools

The cylinder rolling is completed by the upper roller which pressing to the lower one and the mutual rolling.

-

Dust-free packaging machine

This series of packaging machines can perform weighing, metering, and filling operations. Employing a simultaneous weighing and filling design, it is suitable for packaging materials requiring high precision, or those with uneven density, good flowability, or poor flowability. This includes powders and small granules such as protein powder, pharmaceutical powders, powdered additives, starch, solid beverages, icing sugar, monosodium glutamate, veterinary medicines, glucose, toner powder, talcum powder, dyes, flavourings and fragrances, and fine chemical powders.

Hot Products

Focus on providing high-quality machine tools and equipment to the market, covering production and export.

Information Acquisition

Get a Vertical Machining Center from the Manufacturer

Our vertical machining centers are designed according to international standards and delivered to customers with guaranteed quality and perfect after-sales service.

- Manufacturer 100% quality assurance

- Manufacturers have excellent supply chain support

- Sufficient spare parts stock

- Reasonable price

- Fast delivery

- Stronger after-sales support

Anhui Top Made industrial Co.,Ltd.

-

10

+

Industry Experience(year)

-

300

+

Monthly Production Capacity

-

500

+

Serving Customers

Company Advantages

More than ten years of domestic trade accumulation, opening a new journey of foreign trade

-

01

Advantage of Industrial Accumulation

1、Ten years of localization.

Serving more than 500 Chinese manufacturing customers;

Establishing a complete local supply chain verification system;

Accumulating industry know-how database (covering more than 20 sub-sectors); -

02

Advantage of Smart Manufacturing Capability

1.Matrix for all categories of machine tool products.

6 major product lines covering 90% of metal processing scenarios;

Compound processing equipment accounts for 35% (industry average 18%);

2.Adjustable production system.

Monthly production capacity can be adjusted flexibly from 100 to 500 sets;

Fast proofing period ≤ 72 hours (industry standard 120 hours); -

03

Advantage of Quality Control

1.Three-steps quality control system.

Raw material warehousing inspection (qualified rate 99.98%);

Full inspection of key process points (50+ quality control points);

Final inspection dynamic test (72-hour continuous operation test); -

04

Advantages of Foreign Trade Transformation

1.Local experience transplant to globally market.

Upgrade domestic CRM system to multi-language version;

Establish international business department (European and American market experts account for 40%);

2.Strategic resource allocation.

Establishment of a 20 million yuan foreign trade special development fund;

Latest News

Here you can learn the latest information about us

-

How to choose a suitable vertcial machining center and why choose Topmade?

What is vertical maching center? Vertical machining center (VMC) is a high accuracy CNC machine which the spindle axis is perpendicular to the worktable. VMC is widely used in metal machining(milling,drilling,boring ,tapping and s...

2025.12.22 -

2025 Horizontal Machining Center Selection Guide

As manufacturing moves toward greater intelligence and efficiency, the Horizontal Machining Center (HMC) has become widely adopted in industries such as automotive parts, mold manufacturing, construction machinery, and precision machini...

2025.12.11 -

Slant-bed CNC Lathe vs Flat-bed CNC Lathe,which one is suitable for you?

CNC machines are widely used in the parts processing and auto parts industries. However, most customers don't understand the difference between CNC slant-bed lathe and CNC flat-bed lathe. This leads to customers purchasing machines that...

2025.12.05

A Glance of Recent-Delivery

Thank you to every customer who chooses and trusts TOPMADECNC; With a deep sense of mission and responsibility, we use our professional service capabilities to ensure that your machines and equipments are delivered to customers in all regions, providing our global customers with unparalleled economy and convenience.

Global Customers

We are rooted in the Chinese market and have served more than 500 local customers.

FAQ

If your questions are not answered in the below list, please contact us. leanne@topmadetool.com

-

Q

QWhat is your company's business scope?

AOur company mainly deals in CNC products such as CNC lathes, machining centers, and CNC milling machines. We also provide customized equipment solutions based on customer needs. -

Q

QAre you a factory or a trading company?

AWe are an integrated manufacturing and trading company. Initially, we only focused on the domestic market, but with improved production efficiency, we have now expanded into overseas markets, providing our machines to customers worldwide. -

Q

QDo your machines have a warranty period? What services can I expect during the warranty period?

AAll our machines come with a warranty period. During this period, we provide free replacement parts for non-human-caused damage and offer free after-sales consultation. We will respond promptly to any problems you encounter. For parts beyond the warranty period, we will provide them to you at cost price. -

Q

QCan you recommend machines based on my specific needs?

AWe can recommend suitable machines based on your needs. You can tell us your machining drawings, machining processes, and machining cycle time, and our professional engineers will customize a suitable machine for you.

We look forward to your call and consultation.

Fill in the form to send a message

Free solutions for your products.

What Our Clients Say

Deliver good machines, enjoy good life

Basha Joshy Purchase manager

SAUDI ARABIC

We are thrilled to share our experience with TOPMADE’s CNC machinery. Six months ago, we purchased a horizontal machining center, vertical machining center, CNC lathe and milling machine for our production line. The equipment has exceeded expectations in precision, durability, and operational efficiency, significantly boosting our output quality. What truly stands out is the exceptional after-sales support. When we encountered a minor technical issue on vertical machining center last month, your team responded within hours, providing clear remote guidance and dispatching an engineer promptly. The professionalism and patience demonstrated during installation and training were equally impressive. We highly recommend TOPMADE to any business seeking reliable, high-performance CNC machine solutions. Your commitment to innovation and customer satisfaction makes you a trusted partner in manufacturing.

Bobby Kelly Purchase manager

USA

n the fall of 2024, I ordered a CNC bandsaw machine from Anhui Top Made Industrial Co.,Ltd to be used in our handrail production factory. I can confidently verify the exceptional quality and functionality of this machine. It has proven to be a valuable addition to our production process. The professionalism of their sales, service and support team—especially Baccata—has been superb and greatly appreciated. Because of my 100% satisfaction with this experience, I have recently purchased a CK6150 CNC Lathe from them and am already looking to purchase more equipment in the near future.

Michal Štromajer Maintainence Manager

SLOVAKIA

We ordered three sets of machines from Anhui Top Made Industrial Co.,Ltd to use for our production in 2021. Two sets of double columns gantry horizontal saw machine and one turret milling machine During testing, the machines were found to have 100% same performance dimensions as our request. These machines are working as expected ever since, without any problems. Thank you for providing us with such reliable equipment and service support. We are looking forward to TOPMADE’s long-term cooperation.